Refrigerator Panel Sheet Metal Roll Forming Machinery

Basic Info

Model No.: TG-0085

Product Description

Refrigerator Shell Production Line is mainly composed of automatic feeding machine, punching and cutting machine, turning machine, roller mill, Z-L bending machine, U-bending machine, pneumatic system and electronic control system. Specially for the refrigerator side plate production equipment, can adapt to different widths, lengths of the production of products, adjustment is very convenient, easy to operate. Refrigerator Door Panel Roll Forming Machine can shorten the cycle of product development and increase production efficiency, so as to enhance the market competitiveness of enterprises.

At the same time, we will also produce Refrigerator Back Panel Roll Forming Machine, Refrigerator U Profile Sidewall Roll Forming Machine and Refrigerator Side Panel Roll Forming Machine according to customers' requirements.

1. Refrigerator Panel Roll Forming Machine Finished Products

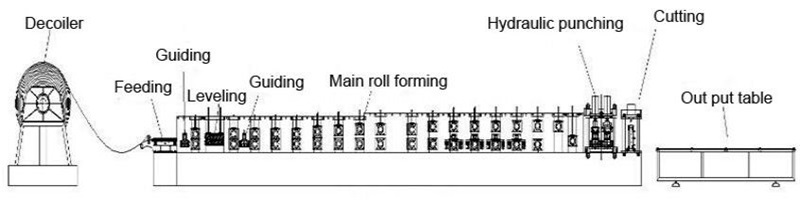

2. The Chart of Process Flow

De-coiler--- Leveling--- Hydraulic Punching--- Roll forming--- Hydraulic Cutting- Output Table

3. The equipment including

| Door Panel Roll Forming Machine | 1 set |

| Electrical control system | 1 set |

| Hydraulic system | 1 set |

| Manual de-coiler | 1 set |

| Leveling machine | 1 set |

| Servo feeding machine | 1 set |

| Press machine | 1 set |

| Cutting device | 1 set |

4. Main technical specification and details

Raw Material: Cold-Rolled Steel, Galvanized Steel

Yield Strength: 235Mpa

Thickness: 0.5mm

Coil Width: 617mm

Plate Length: 1980mm

Coil Inner Diameter: Φ508±20mm

Coil Outer Diameter: ≤Φ1100mm

Coil Weight: ≤ 3Tons

Roll Forming Speed: 10M/min

Length Tolerance: ±2mm

Power Source: 380V±10%, 50-60Hz (according to buyer`s request)

5. Machine Overview

6. Scene application

7. Customer

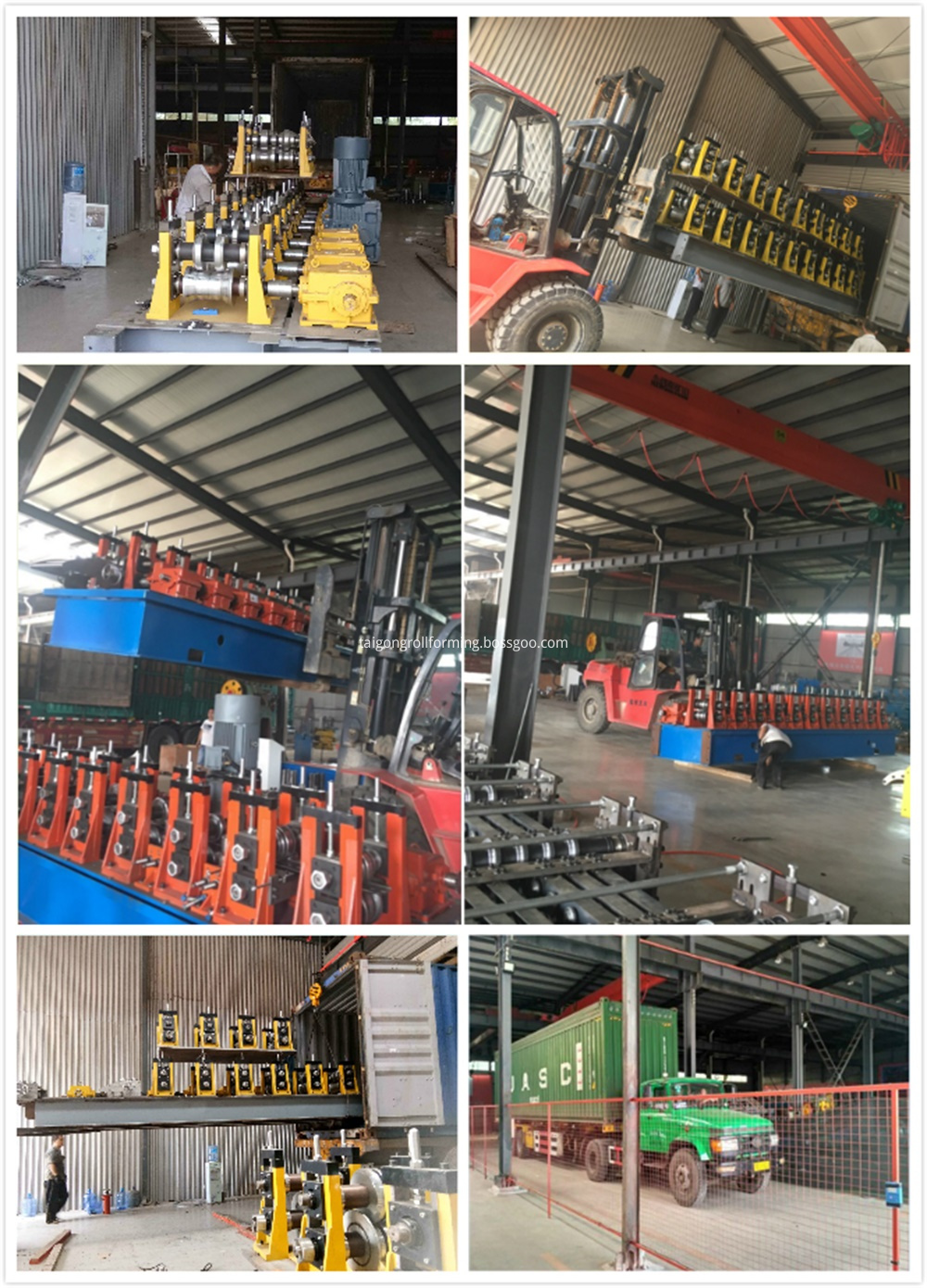

8. Loading

9. Our Service

- 1. Nude, with waterproof cloth and stow-wood. Imported computer control system packed with waterproof cloth and card board.

- 2. This U Shell Forming Machine Line is maintained free of charge for 12 months. When the U Shell Forming Line is used in China, we will install and debug the machine for free; if it is used at abroad, we will send the professional technician to debug. Buyers should take all the fees for technicians travelling abroad.

- 3. All the parts in the Door Frame Machine is free to maintain all the life, if in 12 months our company bear the cost for exchanged the broken part like the new parts cost and express cost, if more than 12 month, we also free to maintain the broken parts but for send the new parts, the buyer need bear the express cost.

- 4. When ship the Refrigerator Door Panel Roll Forming Machine, We will also send one set CD and specification( Chinese and English ) to you with the machine, they can teach you how to operater the machines.

10. Payment terms and after-sale service:

1) FOB Tianjin

2) Payment: 30% T/T deposit, and pay the balance before shipping.

3) Delivery time: 50 working days.

4) Guarantee period: 12 months limited warranty starting from date of delivery. Shipping cost for parts to be replaced during warranty period have to be borne by the customer.

5) Spare parts: bearings, buttons, chains, magnetic valve, protective tube etc

6) Installation and training:

1. If buyers visit our factory and check the machine, we will teach you how to install and us the machine, and also train your workers/technician face to face.

2. Without visiting, we will send you user manual to teach you to install and operate.

3. COST OF INSTALLATION:

The buyer should pay the installation charges ( USD 80 one man one day). To the seller`s appointed account by T/T before the seller`s technicians go to the buyer`s factory. The buyer pays the seller`s technicians travel cost outside China, including round air tickets fee, accommodation and food, provide transportation from living hotel to the work place, necessary communication, and insurance, etc.

Our main products include Stud Track Roll Forming Machines, Steel Frame Forming Machines, Purlin Roll Forming Machines, Welded Pipe Making Machines, Highway Guardrail Roll Forming Machines, Metal Expanded Mesh Production Lines and so on. If you have any further question of our Cold Roll Forming Machine, please feel free to contact me.

Contact us if you need more details on Refrigerator Door Panel Forming Line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Refrigerator Sheet Metal Roll Forming Machine、Refrigerator Metal Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.Product Categories : Refrigerator Shell Production Line > Refrigerator Door Panel Roll Forming Machine