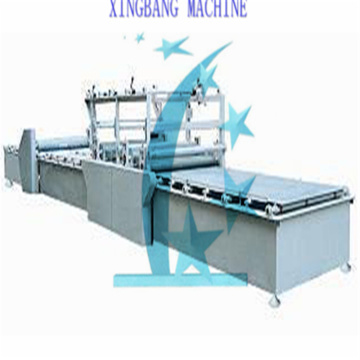

Glass magnesium fire board production line

Basic Info

Model No.: XBD-78569

Product Description

Glass Magnesium Fire Prevention Board Plate Automatic Production Line

1.high degree of automation: the whole production line adopts PLC computer automation control. realized the automatic templates. automatic demoulding agent. coating ingredients. automatic sizing. automatic cloth shop. automatic flat. automatic cutting. automatic picking. automatic pressure plate and other automation function.

2.high output: this production line production speed is adjustable. class output between 1500 and 2600. can be adjusted for production according to the market situation.

3.the specifications of the plate is adjustable. can produce various specifications of 2-40 mm plate. if you have special requirements. can be customized equipment.

4. it can produce many kinds of products: glass magnesium tablet. flue sheet. composite central air-conditioning ventilation pipe plate. strengthen glass magnesium tablet. vitrified microsphere particles insulation board. polystyrene particles insulation board. partition panel. wall insulation board and Other Products.

5. decrease labor: the whole production line adopts PLC computer automation control. 6 people can complete the production task of the whole line. and the intensity of labor is low.

6. precise specification adjustment: each thickness control roller are controlled by digital display. adjust speed. according to the production requirements for the adjustment of the thickness of different specifications. high precision of adjustment.

7. automatic cutting separation: using intelligent cutting system. according to the specifications. automatic cutting and a variety of specifications of products. reduce the amount of labor. improved the precision of products. ensure the production line production quickly.

8. the automatic cleaning template: production line is equipped with automatic cleaning template system. product template is back after logging off and clean like new. Products after demoulding. with dedicated template automatic cleaning equipment for double-sided cleaning template again. to ensure that the thickness of the plank product with precision.

9. automatic unloading board: fully automatic intelligent discharge plate. reduce the labor intensity of workers. prolong the service life of the template. reduce the damage to the plate.

10. automatic pallet packing: according to customer requirements can be realized more specifications. product quantity of pallet packaging.

11. concentrated dust collecting: the whole process of production and the subsequent finishing all have dust removal dust collecting device. to ensure the production of clean environment. reduce the pollution. improve the appearance of the image of enterprises. and collect the dust can be used again. reduce the production cost.

Bo magnesium fire board equipment parameters:

Overall dimensions 16.5m*1.8m*1.6m The installed capacity 11kw Plate specification 6m*1.3m * thick (2-40)mm The work efficiency 2000 m / Class production

Equipment features:

1. Quick adjustment: at any time, you can adjust the thickness you need within 30 seconds while ensuring the accuracy.

2. Uniform stirring: this equipment adopts a special mixer designed for the characteristics of magnesium chloride cement with high power and sufficient mixing of slurry to reduce the deformation rate of sheet materials.

3. Material box feeding: the equipment is equipped with the container, is hydraulic wide material box, blanking noodles wide, material accumulation in the middle of the production line will not result in the phenomenon of lack of material on both sides, therefore, interfere in the layout of don't produced by its thickness, at the same time reduce the risk of sheet deformation.

4. Automatic cutting and separation: the automatic cutting and separation machine is adopted. As it is automatic cutting and separation, the operation risk is greatly reduced and production accidents are avoided.

5. Automatic mounting: automatic rack is combined together, the plate beat to keep quite accuracy for a long time, when the sheet is the initial setting is in the environment of the plane error is not more than 0.02 m, which produce the plate flatness is greatly increased.

Because it is automatic to install shelf additionally, need not manpower, material force, so greatly reduced the damage that man-made causes to plank.

At the same time, the past manual equipment can only produce within 12 mm and the length of no more than 2440mm plate history.

Now our company's equipment, can also produce 10M long, 50mm thick plate specifications.

6. Automatic discharge plate and washing plate: as automatic cleaning template and unloading plate, it reduces the man-made damage to the product and template and ensures and extends the service life of the template.

7. Concentrated dust collecting: in the process of cutting, the dust collecting in cloth bag dust collector, thereby reducing the damage to the production environment, and can make the dust recycling, reduce the pollution phenomenon, reduce the cost.

8. High degree of automation: the whole production line is automatically controlled by PLC computer, which can guarantee the accuracy, size, square degree of products and precision management of various products.

We can offer Building Material Making Machinery

Compound Ventilation Tube Sheet Metal Production Line

Automatic Four Edge Cutting Saw

Large Fireproof Door Core Board Production Line

Fully Automatic New Compound Straw Tile Production Line

Fire Prevention Board Machine Straw Door Equipment

Fire Prevention Board Production Line

Polyurethane Low Pressure Foaming Machine

Polyurethane High Pressure Foaming Machine

Glass Magnesium Fire Prevention Board Plate Automatic Production Line

Glass Magnesium Fire Board Decorating Plate Production Line

Product Categories : Building Material Making Machinery > Glass Magnesium Fire Prevention Board Plate Automatic Production Line